Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Casting – High-purity aluminum ingots are melted and cast into slabs, ensuring superior quality compared to standard Aluminum Coil production.

Hot/Cold Rolling – Plates are precision-rolled to exact thicknesses, offering better formability than Galvalume Steel or Galvanized Steel.

Annealing – Heat treatment enhances ductility, making it more workable than Stainless Steel for complex fabrications.

Cutting & Shaping – Custom-cut to specifications, ideal for applications requiring tighter tolerances than Nickel Strip or Prepainted Steel.

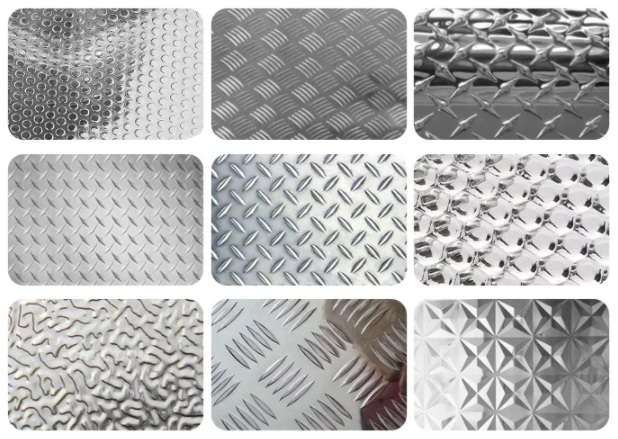

Surface Treatment – Options include anodizing (for corrosion resistance surpassing Galvanized Steel) or polishing (for aesthetic appeal).

Quality Assurance – Rigorous testing ensures compliance with international standards.

China dominates global aluminum consumption, offering exporters:

Massive Market Potential – The world’s largest buyer of Aluminum Products, with demand in construction (replacing Galvalume Steel cladding), automotive (lighter than Stainless Steel), and aerospace.

Cost-Competitive Production – Leverage China’s advanced rolling and coating tech (comparable to Prepainted Steel processes) at competitive prices.

Trade Advantages – Preferential agreements reduce tariffs vs. Nickel Strip or specialty metal imports.

Technology Partnerships – Collaborate with top manufacturers to develop hybrid solutions (e.g., aluminum-Stainless Steel composites).

Diversified Demand – Serve industries from EV batteries (replacing Galvanized Steel components) to high-end packaging.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.