Raw Material Selection: Nickel tubes are manufactured using high-quality nickel alloys. The raw materials are carefully selected based on their composition, purity, and desired properties. Similar to the meticulous selection of nickel alloy raw materials, the production of

Galvalume Steel,

Galvanized Steel,

Aluminum Coil,

Stainless Steel,

Nickel Strip, and

Prepainted Steel also hinges on the careful choice of base materials. Each of these materials has its own set of criteria for raw material selection, ensuring the end products meet the diverse demands of various industries.

Melting and Casting: The selected raw materials are melted in a furnace at high temperatures. The molten metal is then cast into the desired shape, usually in the form of billets or ingots. In the case of Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, and Nickel Strip, their manufacturing processes also involve melting and casting, although the specific alloys and casting techniques may vary according to the unique characteristics of each material. For example, aluminum coils require precise control of melting temperatures to ensure the quality of the final product, while stainless steel casting demands strict adherence to alloy proportions.

Billet/Ingot Rolling: The cast billets or ingots are then rolled into thin strips or plates using hot rolling mills. This process helps to reduce the thickness and increase the length of the metal. Just as nickel billets or ingots are rolled, Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, and Nickel Strip also go through rolling processes, which are crucial for achieving the desired dimensions and mechanical properties. Prepainted Steel, on the other hand, often starts with a pre-rolled base steel that is then coated with paint after rolling to provide both protection and aesthetic appeal.

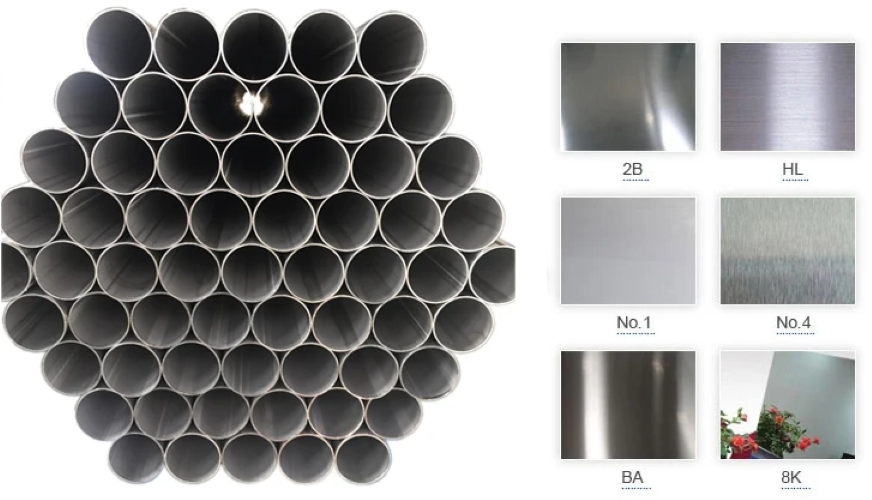

Tube Forming: The rolled metal strips are then formed into tubes using various methods such as cold rolling, cold drawing, or pilgering. In cold rolling, the metal strip is passed through a series of rollers to gradually shape it into a tube. Cold drawing involves pulling the metal strip through a die to achieve the desired tube size and shape. Pilgering is a process where the metal strip is rolled and reduced in size using a pair of rollers. While nickel tubes are formed through these methods, other materials like Galvalume Steel, Galvanized Steel, and Stainless Steel are often used in sheet or coil form for applications such as roofing, structural components, and kitchen appliances, respectively, and do not undergo tube - forming. However, Aluminum Coil can be further processed into various aluminum - based tubes or profiles depending on the application requirements, and Nickel Strip may be used in the production of certain small - scale tubing or as a component in electrical or battery applications.

Heat Treatment: The formed tubes are subjected to heat treatment processes such as annealing or stress relieving. These processes help to improve the mechanical properties and remove any residual stresses in the tubes. Heat treatment is also an important step in the production of Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, and Nickel Strip. It can enhance the strength, ductility, and corrosion resistance of these materials, making them more suitable for their intended uses. For example, heat treatment of stainless steel can improve its resistance to pitting and crevice corrosion, while for aluminum coil, it can optimize its formability.

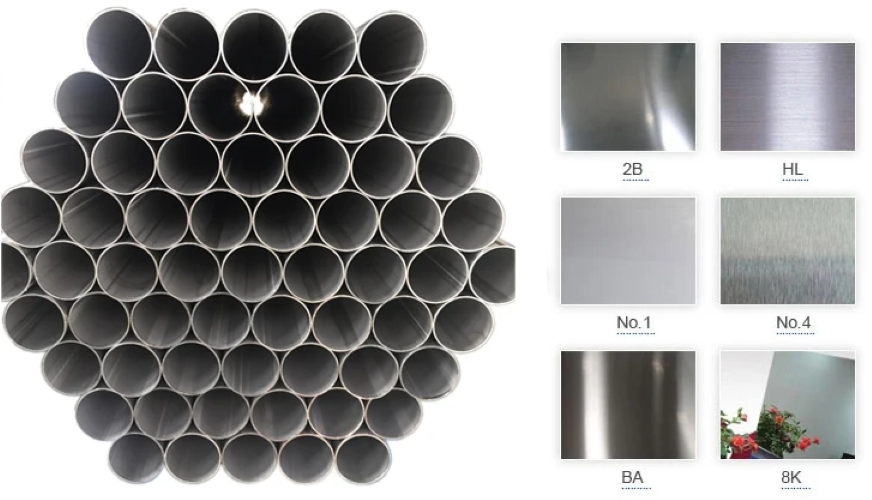

Finishing Operations: The tubes may undergo various finishing operations such as cutting, straightening, and polishing to achieve the desired dimensions and surface finish. Similarly, Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, Nickel Strip, and Prepainted Steel also require finishing operations. Galvalume and galvanized steels may need to be cut to specific lengths for construction projects, aluminum coils may be polished for a better appearance in packaging applications,

Stainless Steel Products are often polished to enhance their hygienic properties, and nickel strips may be cut and shaped for use in electronic devices. Prepainted Steel may undergo additional quality checks to ensure the integrity of the paint coating.

Inspection and Testing: The finished tubes are thoroughly inspected and tested for dimensional accuracy, surface quality, and mechanical properties. This ensures that the tubes meet the required specifications and standards. Quality control is equally vital for Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, Nickel Strip, and Prepainted Steel. These materials are inspected for thickness, coating adhesion, tensile strength, and other key parameters to guarantee their performance and compliance with industry standards.

Packaging and Shipment: The inspected tubes are then carefully packaged to protect them during transportation. They are usually packed in bundles or crates and shipped to customers or distributors. Likewise, Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, Nickel Strip, and Prepainted Steel are packaged appropriately for shipment. Galvalume and galvanized steels are often bundled and wrapped in protective materials, aluminum coils are covered to prevent scratches, stainless

Steel Products are cushioned to avoid damage, and nickel strips are placed in containers to maintain their shape. Prepainted Steel is packaged with care to prevent any damage to the paint finish during transit.

Overall, the production process of nickel tubes involves several stages of melting, casting, rolling, forming, heat treatment, finishing, inspection, and packaging. Each step is crucial in ensuring the quality and performance of the final product. Similarly, the production of Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, Nickel Strip, and Prepainted Steel requires careful attention to every stage of the manufacturing process to meet the diverse needs of different industries and applications.