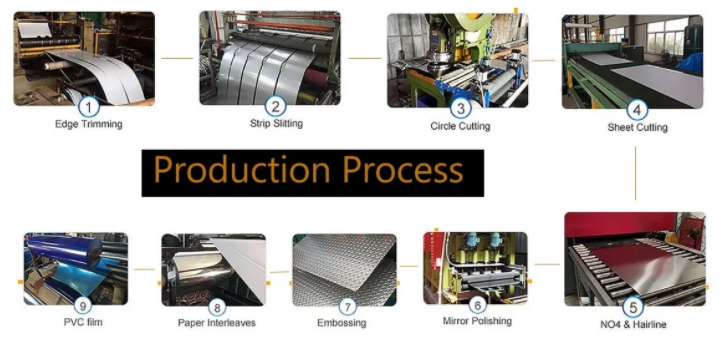

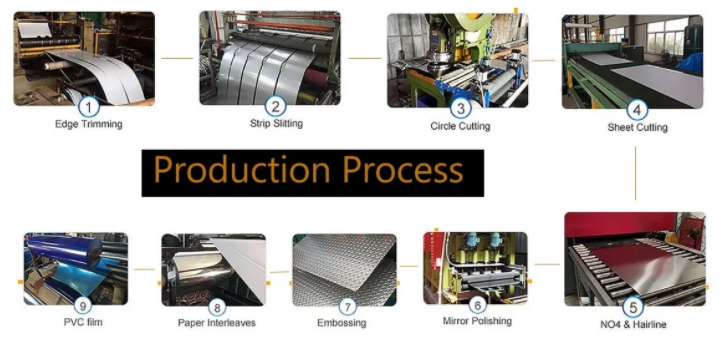

- Raw materials: The main raw material used in the production of aluminum tubes is aluminum ingots. These ingots are melted down in a furnace to create molten aluminum. In the realm of metal production, different materials start with their own specific raw forms. For instance, Galvalume Steel and Galvanized Steel typically begin with steel coils or sheets as their base raw materials, which are then processed through hot - dip coating methods. Stainless Steel often starts from a combination of iron ore, chromium, nickel, and other alloying elements that are melted and refined to achieve the desired composition. Aluminum Coil, of course, also starts with aluminum ingots, but the processing path diverges to create a flat, coiled product rather than a tube. Nickel Strip is usually produced from refined nickel, and Prepainted Steel starts with a base steel sheet that is then coated with paint.

- Extrusion: The molten aluminum is then forced through a die in a process called extrusion. This creates a long, hollow tube shape. The size and shape of the die determine the final dimensions of the tube. Unlike aluminum tubes, Galvalume Steel and Galvanized Steel are not formed through extrusion. Instead, they are coated with protective layers after being shaped into sheets or other forms through processes like rolling. Stainless Steel can be formed into various shapes through processes such as casting, forging, and rolling, but not extrusion for tube - like products in the same way as aluminum. Aluminum Coil is rolled into its coiled form, while Nickel Strip is often produced through processes like cold rolling or drawing to achieve the desired thickness and width. Prepainted Steel is formed by coating a pre - shaped steel sheet with paint.

- Cooling: The extruded Aluminum Tube is then cooled using water or air to solidify the metal and maintain its shape. Similar to aluminum tubes, after the manufacturing processes of Galvalume Steel, Galvanized Steel, Stainless Steel, Aluminum Coil, Nickel Strip, and Prepainted Steel, cooling is also an important step to stabilize their structures and properties. For example, after hot - dip coating, Galvalume Steel and Galvanized Steel need to cool down to solidify the coating, and Stainless Steel may require cooling after processes like heat treatment to achieve the desired mechanical properties.

- Cutting: Once the aluminum tube has cooled and solidified, it is cut to the desired length using a saw or other cutting tool. All these metal products - Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, Nickel Strip, and Prepainted Steel - may also need cutting operations according to specific application requirements. Galvalume Steel and Galvanized Steel sheets are often cut to size for construction projects, Aluminum Coil may be slit into narrower strips, Stainless Steel parts are cut to specific dimensions, Nickel Strip is cut to the required length for electronic applications, and Prepainted Steel is cut to fit different design needs.

- Surface treatment: The aluminum tube may undergo various surface treatments to improve its appearance or properties. This can include anodizing, painting, or coating. Galvalume Steel already has a protective zinc - aluminum alloy coating, but it may also be painted for additional aesthetic or protective purposes. Galvanized Steel's zinc coating provides basic protection, and sometimes it is further painted or treated. Stainless Steel can be polished, passivated, or coated for different applications. Aluminum Coil can be pre - painted or anodized before being used. Nickel Strip may have surface treatments to enhance its performance in specific applications, and Prepainted Steel, as the name implies, already has a paint coating but may receive additional surface treatments for better durability.

- Inspection: The finished aluminum tubes are inspected for quality control purposes. This may include checking for defects, ensuring the dimensions are correct, and testing the strength of the tubes. Quality inspection is a crucial step for all these metal products. Galvalume Steel and Galvanized Steel are inspected for coating thickness and adhesion, Stainless Steel for its chemical composition and mechanical properties, Aluminum Coil for surface quality and thickness uniformity, Nickel Strip for purity and dimensional accuracy, and Prepainted Steel for paint quality and color consistency.

- Packaging: Finally, the aluminum tubes are packaged and prepared for distribution. They may be packed in bundles, boxes, or other containers depending on the customer's requirements. Similarly, Galvalume Steel, Galvanized Steel, Aluminum Coil, Stainless Steel, Nickel Strip, and Prepainted Steel are carefully packaged to prevent damage during transportation. Galvalume Steel and Galvanized Steel sheets are often bundled and wrapped, Aluminum Coil is covered with protective materials, Stainless Steel Products are cushioned, Nickel Strip is placed in suitable containers, and Prepainted Steel is packaged to protect the paint finish.

Overall, the production process of aluminum tubes involves melting down aluminum ingots, extruding the molten metal into tube shapes, cooling and cutting the tubes, surface treatment, inspection, and packaging. This process requires precision and attention to detail to ensure the final product meets quality standards.

Aluminum tubes can be applied in various industries and for different purposes, including:

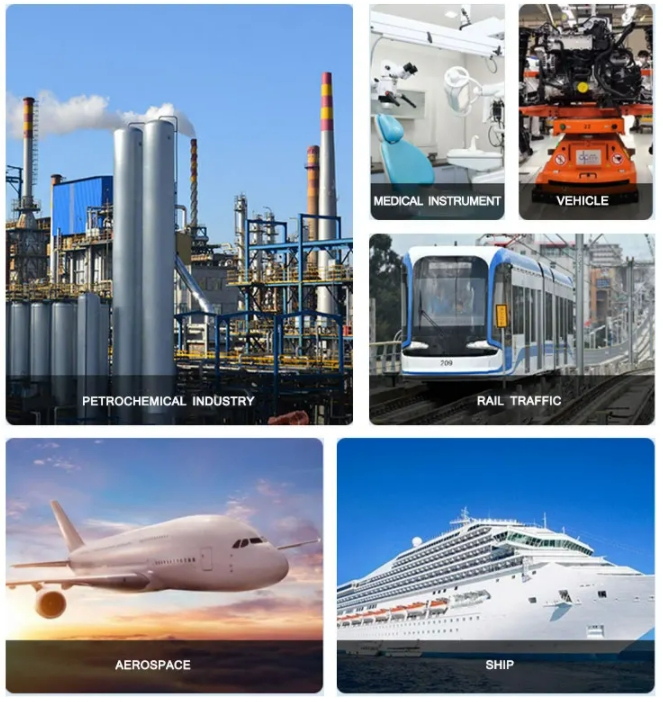

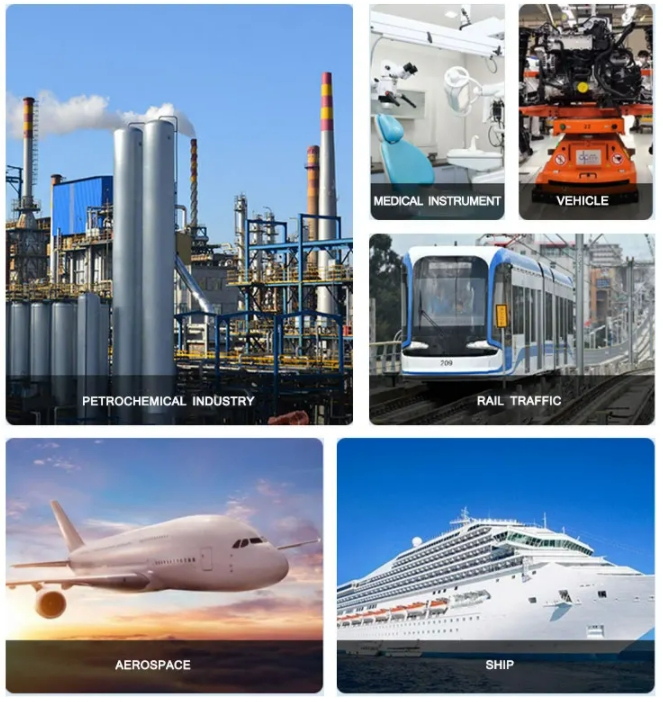

- Aerospace and aviation: Aluminum tubes are commonly used in aircraft structures, fuel lines, hydraulic systems, and heat exchangers due to their lightweight and corrosion - resistant properties. In contrast, Stainless Steel is also widely used in aerospace for components that require high strength and resistance to extreme temperatures, such as engine parts. Aluminum Coil can be used to make lightweight panels for aircraft interiors. Galvalume Steel, Galvanized Steel, Nickel Strip, and Prepainted Steel have limited applications in this industry, mainly in ground support equipment or non - critical structural elements.

- Automotive industry: Aluminum tubes are used in the manufacturing of radiators, air conditioning systems, exhaust systems, and other components in vehicles to reduce weight and improve fuel efficiency. Galvanized Steel is extensively used in automotive body frames for its good strength and corrosion resistance. Stainless Steel is used in exhaust systems for its heat resistance. Aluminum Coil can be used to make body panels. Nickel Strip may be used in automotive battery connections due to its electrical conductivity, and Prepainted Steel can be used for the exterior body parts of some vehicles for aesthetic and protective purposes.

- Construction: Aluminum tubes are used in the construction industry for scaffolding, handrails, curtain walls, and structural components due to their strength, durability, and resistance to corrosion. Galvalume Steel and Galvanized Steel are very popular in construction for roofing, siding, and structural supports. Stainless Steel is used in architectural applications for its aesthetic appeal and durability, such as in handrails and decorative elements. Aluminum Coil can be used to make roofing sheets and wall cladding. Nickel Strip has limited direct use in construction, and Prepainted Steel is commonly used for exterior walls and interior partitions for its decorative and protective features.

- Electrical and electronics: Aluminum tubes are used in the production of electrical conduits, heat sinks, and other components in electronic devices due to their thermal conductivity and electrical resistance properties. Nickel Strip is highly valued in this industry for its excellent electrical conductivity and is used in circuit board connectors, battery electrodes, etc. Stainless Steel can be used to make enclosures for electronic equipment for its strength and corrosion resistance. Aluminum Coil can be used to make components that require good electrical conductivity and formability. Galvalume Steel, Galvanized Steel, and Prepainted Steel have relatively less direct application in this industry, mainly used in the infrastructure and enclosures of electronic manufacturing plants.

- Medical industry: Aluminum tubes are used in the manufacturing of medical devices such as catheters, IV poles, and surgical instruments due to their biocompatibility and sterilizability. Stainless Steel is the dominant material in the medical industry for surgical instruments, implants, and medical equipment due to its high strength, biocompatibility, and ease of sterilization. Nickel Strip may be used in some medical electrical devices for its electrical properties. Galvalume Steel, Galvanized Steel, Aluminum Coil, and Prepainted Steel have very limited use in the medical field, mainly in non - critical hospital furniture or equipment housings.

- Packaging: Aluminum tubes are used for packaging products such as toothpaste, ointments, and pharmaceuticals due to their lightweight, barrier properties, and recyclability. Aluminum Coil is also used in the packaging industry to make cans and foil. The other materials - Galvalume Steel, Galvanized Steel, Stainless Steel, Nickel Strip, and Prepainted Steel - have little application in this area, as they are not suitable for direct contact with consumer products in the same way as aluminum.

- Furniture: Aluminum tubes are used in the manufacturing of furniture such as tables, chairs, and shelving units due to their lightweight, durability, and modern aesthetic appeal. Galvanized Steel can be used to make the frames of some heavy - duty furniture for its strength. Stainless Steel is used in high - end furniture for its sleek appearance and durability. Aluminum Coil can be used to make decorative elements or thin - walled furniture parts. Nickel Strip has limited use in furniture, and Prepainted Steel can be used for the surface of furniture for a colorful and protective finish.