Stainless Steel is produced through a series of steps that involve melting, refining, casting, and finishing. In the realm of metal production, different materials like

Galvalume Steel,

Galvanized Steel,

Aluminum Coil,

Nickel Strip, and

Prepainted Steel also have their unique manufacturing processes, yet share some similarities in the pursuit of creating high - quality products. The production process of stainless steel typically involves the following steps:

- Melting: The raw materials used in stainless steel production, such as iron ore, coal, and limestone, are melted in a furnace at high temperatures. This process helps to remove impurities and create a molten metal. In contrast, Galvalume Steel and Galvanized Steel start with steel coils or sheets which are then coated with a zinc - aluminum alloy (for Galvalume Steel) or pure zinc (for Galvanized Steel) through hot - dip processes. Aluminum Coil production begins with melting aluminum ingots, similar to the initial step of stainless steel, but the subsequent processes diverge. Nickel Strip is produced from refined nickel, which is melted and then processed further. Prepainted Steel starts with a base steel sheet that is prepared before the paint application process, and doesn't involve the same complex melting of multiple raw materials as stainless steel.

- Refining: The molten metal is then refined to adjust the composition and remove any remaining impurities. This is done through processes such as desulfurization, degassing, and alloying to achieve the desired properties of the stainless steel. While Galvalume Steel and Galvanized Steel don't require the same level of internal composition adjustment through refining as stainless steel, they do need to ensure the quality of the coating application. Aluminum Coil refining focuses on purifying the aluminum to meet specific quality standards for its various applications. Nickel Strip may undergo refining processes to enhance its purity and properties suitable for electronics and other high - tech applications. Prepainted Steel, after ensuring the base steel quality, focuses on the proper adhesion and quality of the paint coating during its production process.

- Casting: Once the metal has been refined, it is poured into molds to form ingots or slabs. These molds are then cooled and solidified to create the initial shape of the stainless steel. Galvalume Steel and Galvanized Steel, after coating, may be formed into various shapes through rolling or other shaping processes rather than traditional casting. Aluminum Coil is often cast into slabs first and then rolled into coils. Nickel Strip is usually formed through processes like rolling or drawing after melting and refining, and doesn't follow the same casting process as stainless steel. Prepainted Steel is formed by first shaping the base steel sheet and then applying the paint coating.

- Hot rolling: The solidified metal is then reheated and passed through a series of rollers to reduce its thickness and shape it into the desired form, such as sheets, plates, or coils. Galvalume Steel, Galvanized Steel, and Aluminum Coil also undergo hot rolling processes as part of their production to achieve the right thickness and shape. Nickel Strip may be hot - rolled in some cases to start the shaping process, but its thin and flat nature often requires more specific cold - working processes later. Prepainted Steel may be hot - rolled before painting to ensure the base steel has the right properties.

- Cold rolling: The hot - rolled stainless steel is then further processed through cold rolling to improve its surface finish, dimensional accuracy, and mechanical properties. This process involves passing the metal through a series of rollers at room temperature. Galvalume Steel, Galvanized Steel, and Aluminum Coil can also be cold - rolled to enhance their surface quality and achieve more precise dimensions. Nickel Strip is commonly cold - rolled to reach the required thickness and improve its mechanical properties for applications in electronics and batteries. Prepainted Steel may undergo cold - rolling after painting in some cases to ensure the final product meets the required specifications.

- Annealing: The cold - rolled stainless steel is then annealed to relieve internal stresses and improve its ductility and formability. This process involves heating the metal to a specific temperature and then cooling it slowly to achieve the desired properties. Annealing is also an important process for Galvalume Steel, Galvanized Steel, Aluminum Coil, and Nickel Strip to improve their mechanical properties, although the temperature and time parameters may vary depending on the material. Prepainted Steel may not require annealing in the same way as the other metals, as the focus is more on the paint coating integrity and the base steel's properties.

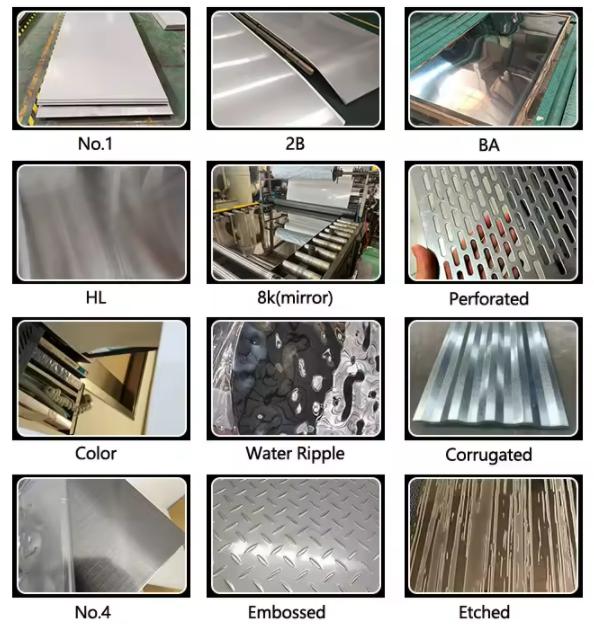

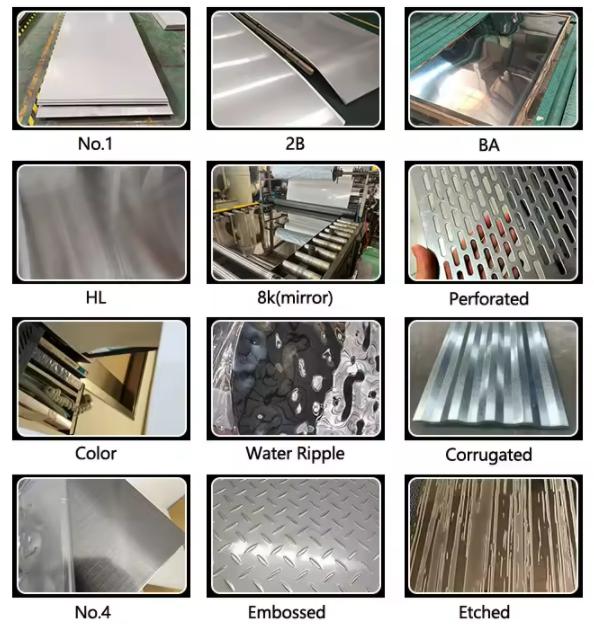

- Finishing: The final step in the production process involves finishing the stainless steel to achieve the desired surface finish and appearance. This can include processes such as polishing, grinding, or coating to enhance the aesthetic appeal of the stainless steel. Galvalume Steel has its characteristic metallic finish from the zinc - aluminum coating, but can also be further processed for specific looks. Galvanized Steel may be painted or have a protective clear coat applied for better appearance and protection. Aluminum Coil can be anodized, painted, or polished. Nickel Strip may be cleaned, passivated, or have a protective coating applied. Prepainted Steel, of course, already has its paint finish, but may undergo additional processes like edge - sealing or embossing for better performance and appearance.

Overall, the production process of stainless steel involves a combination of melting, refining, casting, and finishing to create a durable and corrosion - resistant material that is widely used in various industries. Similarly, Galvalume Steel, Galvanized Steel, Aluminum Coil, Nickel Strip, and Prepainted Steel each have their own production journeys, tailored to meet the specific requirements of their diverse applications across different sectors.